Envíanos un correo electrónico :

info@labcompanion.cn-

-

Solicitar una llamada :

+86 18688888286

150L Rapid Temperature Change Test Chamber

This 150L rapid temperature change test chamber is designed for components in electronics, automotive, aerospace, metals, and other industries. It performs rapid temperature change, gradient adaptability, and temperature stress screening tests to evaluate product performance for design, improvement, and inspection. With water cooling and a Q8 touch controller, it achieves a linear heating/cooling rate of ≥12.5℃/min at a 10kg load.

Número de artículo :

T-150-12-12WOrden (MOQ) :

1Origen del producto :

ChinaColor :

White150L Rapid Temperature Change Chamber 12.5℃/min

|

Temperature range |

-70℃~+150℃ |

|

Temperature fluctuation |

± 0.5℃ |

|

Temperature uniformity |

≤2℃ |

|

Temperature deviation |

± 2℃ |

|

Heating rate |

≥12.5℃ / min (-40~85℃The whole average heating, load 10 KG aluminumingot) |

|

Cooling rate |

≥12.5℃ / min (85~ -40℃The whole average heating, load 10 KG aluminumingot) |

|

Working volume |

150L |

|

Internal dimension |

W:600mm × H:500mm × D:500mm |

|

External dimension |

W:850mm × H:1950mm × D:1730mm |

150L Rapid Temperature Chamber Water Cooled Q8

Features of the Rapid Temperature Change Test Chamber:

Refrigeration System:

The air supply mode inside the test chamber adopts an upper air supply and lower return air cooling system.

Refrigeration System and Compressor: To ensure the test chamber’s cooling rate and minimum temperature requirements, this chamber is equipped with a binary cascade air-cooled refrigeration system driven by Taikang hermetic compressors. The cascade refrigeration system consists of a high-temperature refrigeration cycle and a low-temperature refrigeration cycle, connected by an evaporative condenser, which also serves as the energy transfer medium. Heat from the working chamber is removed via the two-stage refrigeration system to achieve the target temperature.

The refrigeration system design incorporates energy regulation technology, an effective solution that ensures stable and normal operation of the refrigeration unit. This reduces the operating cost and failure rate of the refrigeration system to an economically optimal level.

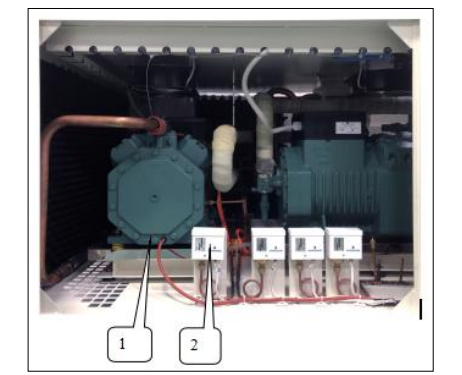

(refrigeration room )

|

Number |

Name |

Illustrate |

|

1 |

Compression engine |

Compression refrigeration |

|

2 |

Pressure protection controller |

When the pressure in the pipeline is too high or too low, the equipment will call the police |

Environmental Chamber Temperature Humidity Control

Intelligent Controller Environmental Chamber

150L High Speed Temperature Cycling Test Chamber

It is temperature and humidity programmable controller which equips with the general control, heating and cooling function by supporting high definition TFT-LCD touch screen and SD card.

Performance:

High accuracy

Precision control with 18bit A/D convertor

TEMP. : ±0.1% of full scale ±1 digit

HUMI. : ±1.0% of full scale ±1digit

Optimizing PID group

Precision control by 6 groups of TEMP./HUMI. and 3 group of temperature only

Specialized controller

As a specialized controller for temperature and humidity, synchronized control system with PT-PT, PT-DCV

Specialized humidity control

Humidity control algorithm implements a stable control according to the equipment size。

Heating cooling control

Configuration separated by display, control, and input / output board

Available to mount panel mount and VESA mount