Envíanos un correo electrónico :

info@labcompanion.cn-

-

Solicitar una llamada :

+86 18688888286

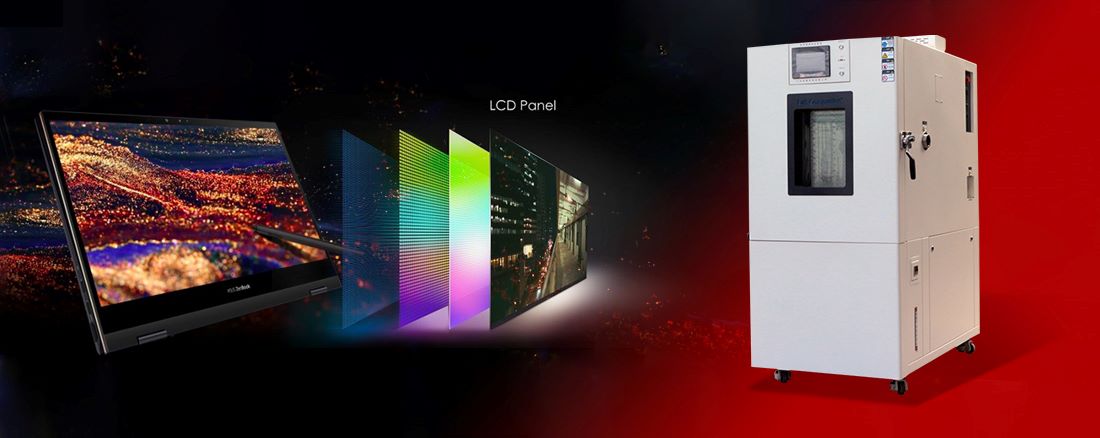

Soluciones para pruebas de confiabilidad de computadoras industriales - Productos electromecánicos

Soluciones para pruebas de confiabilidad de computadoras industriales

Las computadoras industriales se pueden dividir en tres categorías según sus atributos de aplicación:

(1) Clase de placa: incluye computadora de placa única (SBC), placa integrada (Embedded Board), Black Plane, módulo PC/104.

(2) Clase de subsistema: incluye computadoras de placa única, placas, chasis, fuentes de alimentación y otros periféricos combinados en subsistemas operativos, como servidores industriales y estaciones de trabajo.

(3) Soluciones de integración de sistemas: se refiere a un conjunto de sistemas desarrollados para un sector profesional, que incluye el software y el hardware necesarios, así como su entorno, como los cajeros automáticos (ATM). Las aplicaciones de las computadoras industriales abarcan ampliamente cajeros automáticos, puntos de venta (TPV), equipos médicos electrónicos, máquinas de juego, equipos de apuestas, etc. La multiplicidad de sectores de la industria exige que las computadoras industriales sean resistentes a la luz solar, altas y bajas temperaturas, humedad y otros entornos. Por ello, las pruebas de fiabilidad pertinentes son la prioridad de diversos fabricantes en sus investigaciones y desarrollos.

Pruebas de confiabilidad comunes para computadoras industriales:

Prueba de temperatura amplia

Amplio rango de temperatura: según el entorno de aplicación, se puede dividir en cuatro categorías: 1. Exterior: especialmente para zonas con temperaturas extremadamente bajas o altas, como el norte de Europa y países desérticos, el rango de temperatura puede variar de -50 a 70 °C. 2. Espacios confinados: por ejemplo, donde se genera una fuente de calor, como cerca de una caldera, el rango de temperatura máxima es de aproximadamente 70 °C. 3. Equipos móviles: como equipos de vehículos, la temperatura máxima puede alcanzar los 90 °C. 4. Entornos especialmente hostiles: como equipos aeroespaciales y equipos de perforación petrolera.

Prueba de estrés por envejecimiento

Prueba de estrés por envejecimiento: el rango de temperatura es de -40 °C a 85 °C y la tasa de variación de temperatura es de 10 °C por minuto para pruebas cíclicas.

Máquina de temperatura y humedad constantes - tipo estándar

El propósito de la máquina es simular el producto bajo las condiciones combinadas de temperatura y humedad en el entorno climático (operación y almacenamiento a alta y baja temperatura, ciclo de temperatura, alta y alta humedad, baja y baja temperatura, prueba de rocío, etc.), para detectar si la adaptabilidad y las características del producto han cambiado. ※ Debe cumplir con los requisitos de las normas internacionales (IEC, JIS, GB, MIL, etc.) Para lograr la consistencia internacional de los procedimientos de medición (incluidos los procedimientos, condiciones y métodos de prueba).

Elemento de prueba: Prueba de temperatura amplia

Máquina de choque térmico - máquina de prueba de detección de tensión

El cribado de tensión por ciclos de temperatura es el producto en el límite de resistencia de diseño, el uso de tecnología de aceleración de temperatura (en los extremos superior e inferior de temperatura del ciclo, el producto produce expansión y contracción alternas) para cambiar la tensión ambiental externa, de modo que el producto produzca tensión térmica y deformación, al acelerar la tensión para hacer que surjan los posibles defectos en el producto [posibles defectos de material de las piezas, defectos de proceso, defectos de proceso], para evitar que el producto en el proceso de uso, la prueba de tensión ambiental a veces conduce a fallas, causando pérdidas innecesarias, para mejorar el rendimiento de entrega del producto y reducir el número de reparaciones tiene un efecto significativo, además, el cribado de tensión en sí mismo es un proceso de etapa del proceso. Más que una prueba de confiabilidad, el cribado de tensión es un procedimiento 100% realizado en el producto.

Elemento de prueba: Prueba de estrés por envejecimiento