Envíanos un correo electrónico :

info@labcompanion.cn-

-

Solicitar una llamada :

+86 18688888286

Las condiciones ambientales tienen una gran influencia en la funcionalidad y fiabilidad de los componentes, dispositivos y sistemas electrónicos. A menudo, una prueba de temperatura normal no es suficiente para detectar puntos débiles latentes lo más rápido posible. Las muestras deben estar sujetas a múltiples cambios de temperatura similares a impactos. Con la cámara de prueba de choque térmico se pueden lograr cambios de temperatura extremadamente rápidos de –55 °C a +150 °C. Esto le ayuda a reducir los fallos tempranos y aumentar la fiabilidad de sus productos. Reproducible, certificado y en condiciones aceleradas.

Número de artículo :

TS2-60-40AOrden (MOQ) :

1Origen del producto :

ChinaColor :

WhiteCaracterísticas técnicas:

|

Dimensiones (mm) |

Ancho |

Altura |

Profundidad |

|

Útil |

460 |

350 |

300 |

|

En general |

1006 |

2120 |

1800 |

Rango de temperatura y humedad:

Rango de temperatura del tanque de prueba: -70 ℃ ~ 180 ℃.

Rango de choque térmico: -40 ℃ ~ 150 ℃

Rango de ajuste de temperatura del tanque de alta temperatura: 60 ℃ ~ 180 ℃

Rango de ajuste de temperatura del tanque de baja temperatura: -70 ℃ ~ -10 ℃.

Tiempo de calentamiento del tanque a alta temperatura desde RT (temperatura ambiente) hasta 180 ℃: ≤ 45/min

Tanque de baja temperatura Tiempo de enfriamiento desde RT (temperatura ambiente) hasta -70 ℃: ≤50 min

Estabilidad de temperatura: ±0,5 ℃.

Uniformidad de temperatura: ±2,0 ℃.

Tiempo de recuperación de temperatura de -40 a 150 °C: ≤ 3 min (sin carga)

El tiempo de choque térmico constante de alta y baja temperatura es de más de 15 minutos.

Condiciones estándar de uso:

Utilice la temperatura ambiente: 5 ~ 30 ℃

Otros parámetros:

1. Modelo de controlador: pantalla táctil a color Q8

2. Modelo de compresor: ZF13KQE*2

Refrigerante: R-404A/R23

3. Temperatura de calefacción eléctrica (H): 10,8 KW

Calefacción eléctrica de temperatura (L): 7,2 KW.

Especificaciones de la fuente de alimentación:

CA 380 V, 50/60 HZ, 3 ∮ 5 hilos

Corriente nominal:

CA 27 A, potencia 18 KW

Esta máquina está dedicada a la fuente de alimentación marcada anteriormente; utilícela de acuerdo con la distribución de energía nominal. Si se cambia el área de uso, comuníquese con nuestra empresa. Teléfono de servicio 400-628-2786.

Construcción de una cámara de prueba de choque térmico de dos zonas:

1, modo de construcción de la cámara de pruebas ambientales:

La cámara de prueba ambiental se compone de una cámara de prueba de alta temperatura ubicada en el extremo superior, una cámara de prueba de baja temperatura ubicada debajo, un gabinete congelador ubicado en la parte posterior y una cámara de control de electrodomésticos (software del sistema) ubicada a la derecha. De esta manera, la carcasa ocupa un área pequeña, estructura compacta, diseño de apariencia hermosa, la unidad del congelador se coloca en un cuerpo de cámara del generador separado, para reducir la vibración y el ruido del funcionamiento de la unidad del congelador en el daño de la cámara de prueba ambiental. además de la instalación y mantenimiento del grupo electrógeno, el panel de operación de electrodomésticos se coloca en el panel derecho de la cámara de pruebas ambientales para facilitar la operación real;

2, Materias primas de la superficie de la carcasa: placa laminada en frío, solución de pulverización de polvo electrostático de superficie;

3, materias primas de la cavidad de la carcasa: placa de acero inoxidable importada (SUS304);

4, material de aislamiento térmico: espuma de éster de poliamina de plástico duro resistente al calor + placa de espuma de vidrio;

5, la puerta: puerta simple, equipada con doble sellado de caucho de silicona y equipo de calentamiento con tira de caucho de sellado, debajo de la zona de calentamiento de temperatura autolimitada, para evitar la esencia del experimento y las heladas;

6, rejilla de prueba: mueva hacia arriba y hacia abajo la rejilla de prueba de placa de acero inoxidable deslizante izquierda y derecha. El cilindro neumático de doble efecto muestra una fuerza motriz estable y simétrica. El dispositivo de posicionamiento del bastidor de prueba utiliza un interruptor de límite activado por un campo electromagnético;

7, Orificio de instalación del cable: el extremo superior del bastidor de prueba y la parte superior de la cámara de prueba de alta temperatura están provistos de un tubo telescópico para pasar el cable.

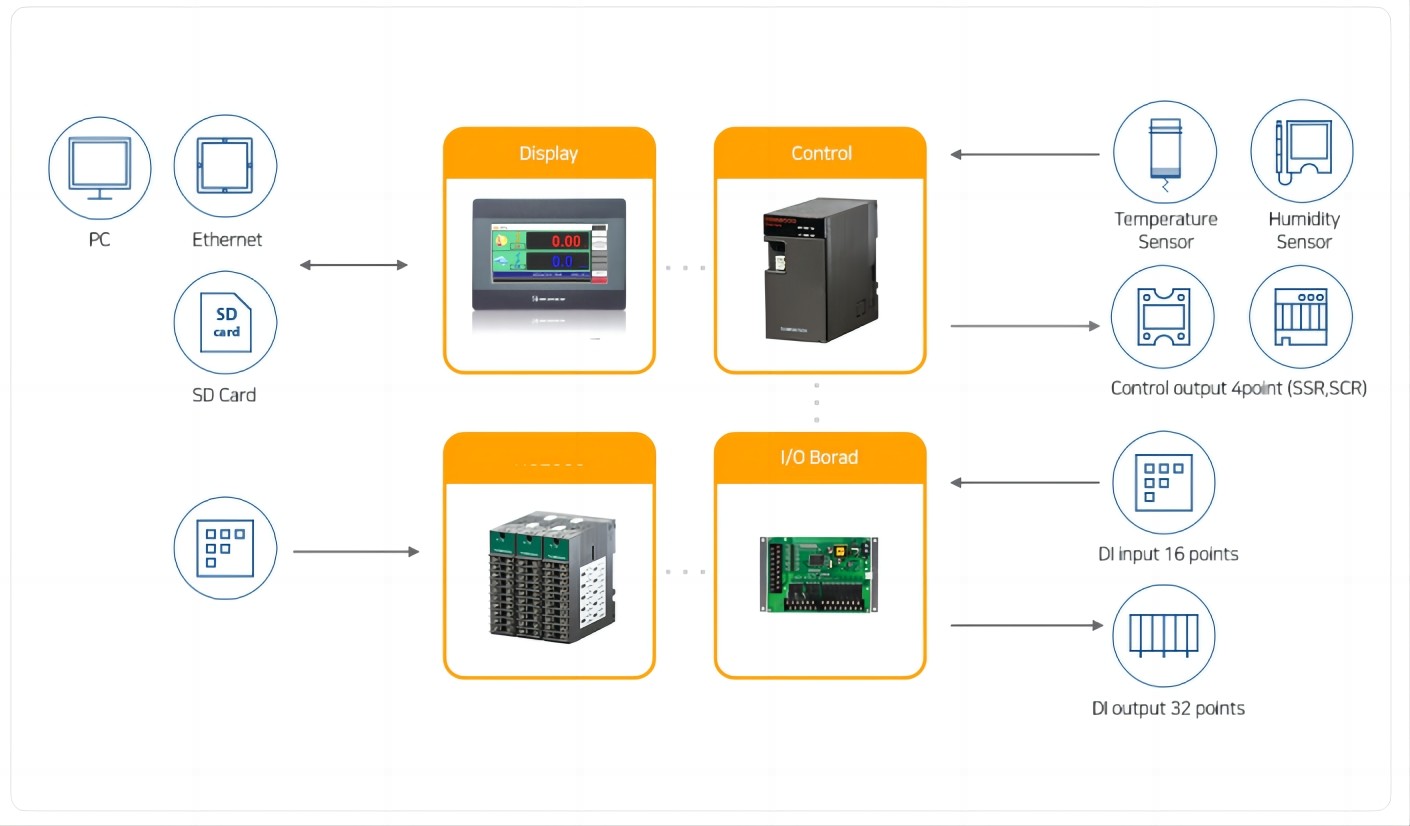

Controlador de temperatura y humedad programable tipo táctil

Es un controlador programable de temperatura y humedad que está equipado con funciones de control general, calefacción y refrigeración al admitir una pantalla táctil TFT-LCD de alta definición y una tarjeta SD.

Actuación:

Alta precisión

Control de precisión con convertidor A/D de 18 bits

TEMPERATURA. : ±0,1% de la escala completa ±1 dígito

HUMÍ. : ±1,0% de la escala completa ±1 dígito

Optimización del grupo PID

Control de precisión por 6 grupos de TEMP./HUMI. y 3 grupos de temperatura solamente

Controlador especializado

Como controlador especializado de temperatura y humedad, sistema de control sincronizado con PT-PT, PT-DCV

Control de humedad especializado

El algoritmo de control de humedad implementa un control estable según el tamaño del equipo.

Control de enfriamiento de calefacción

Hardware separado

Configuración separada por display, control y placa de entrada/salida

Disponible para montaje en panel y montaje VESA